Sharper Images, Smarter Reads: Reliable Deep Learning OCR With TIS Cameras, Theia Optics, and Zebra Aurora Vision Studio

Published on October 15, 2025 by TIS Marketing.

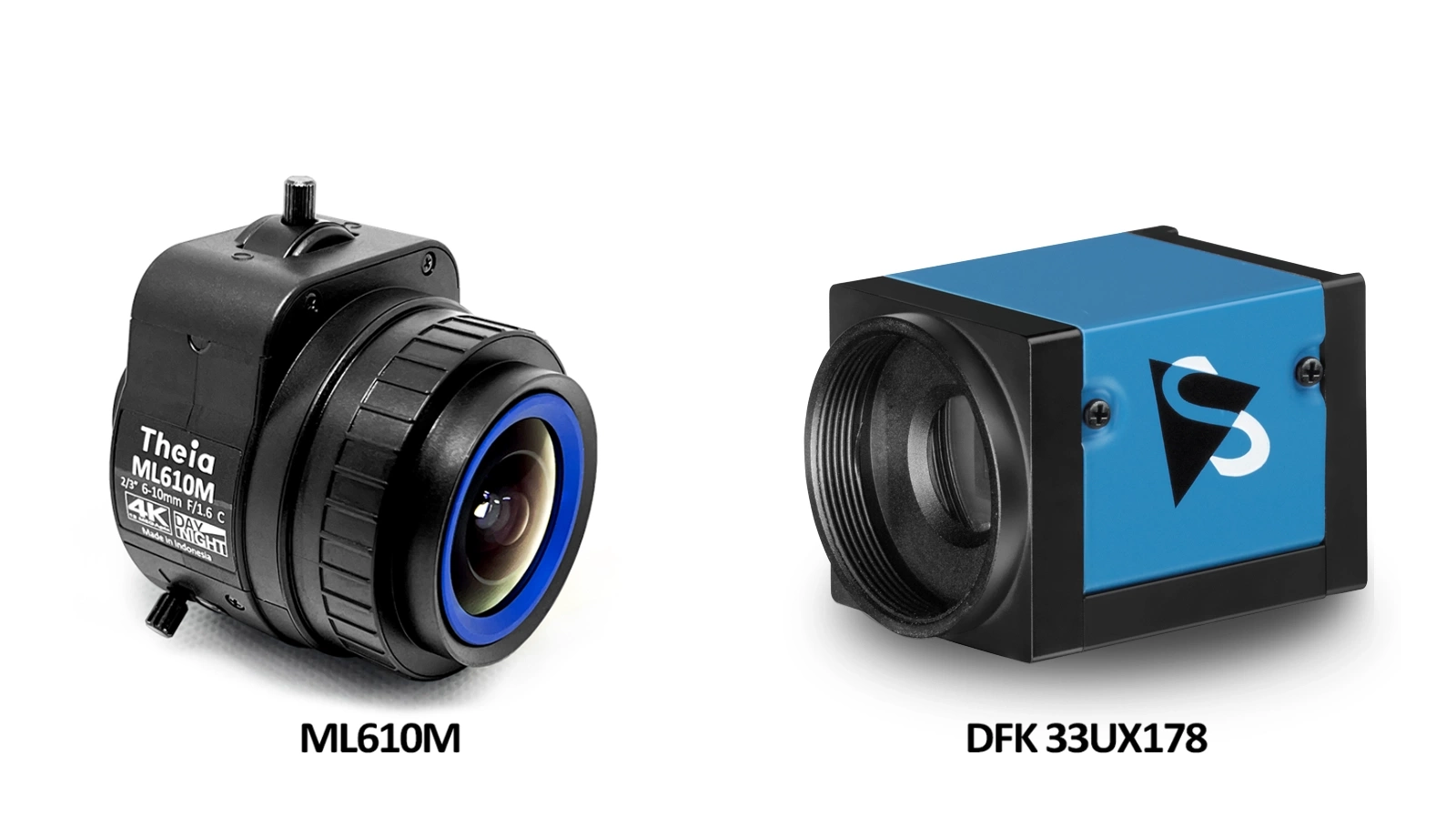

Optical character recognition (OCR) systems are key to traceability and quality control in modern manufacturing and logistics. Characters are often small, densely printed, low contrast, or printed on reflective materials, making consistent detection difficult. To evaluate how optical precision influences deep learning-based OCR, colleagues in The Imaging Source's US offices tested a configuration combining the The Imaging Source DFK 33UX178 industrial camera, Theia Technologies' ML610M varifocal 4K lens, and Zebra's Aurora Vision Studio (a software distributed by The Imaging Source, LLC in North America).

Image Quality as the Foundation for Deep Learning

Image Quality as the Foundation for Deep Learning

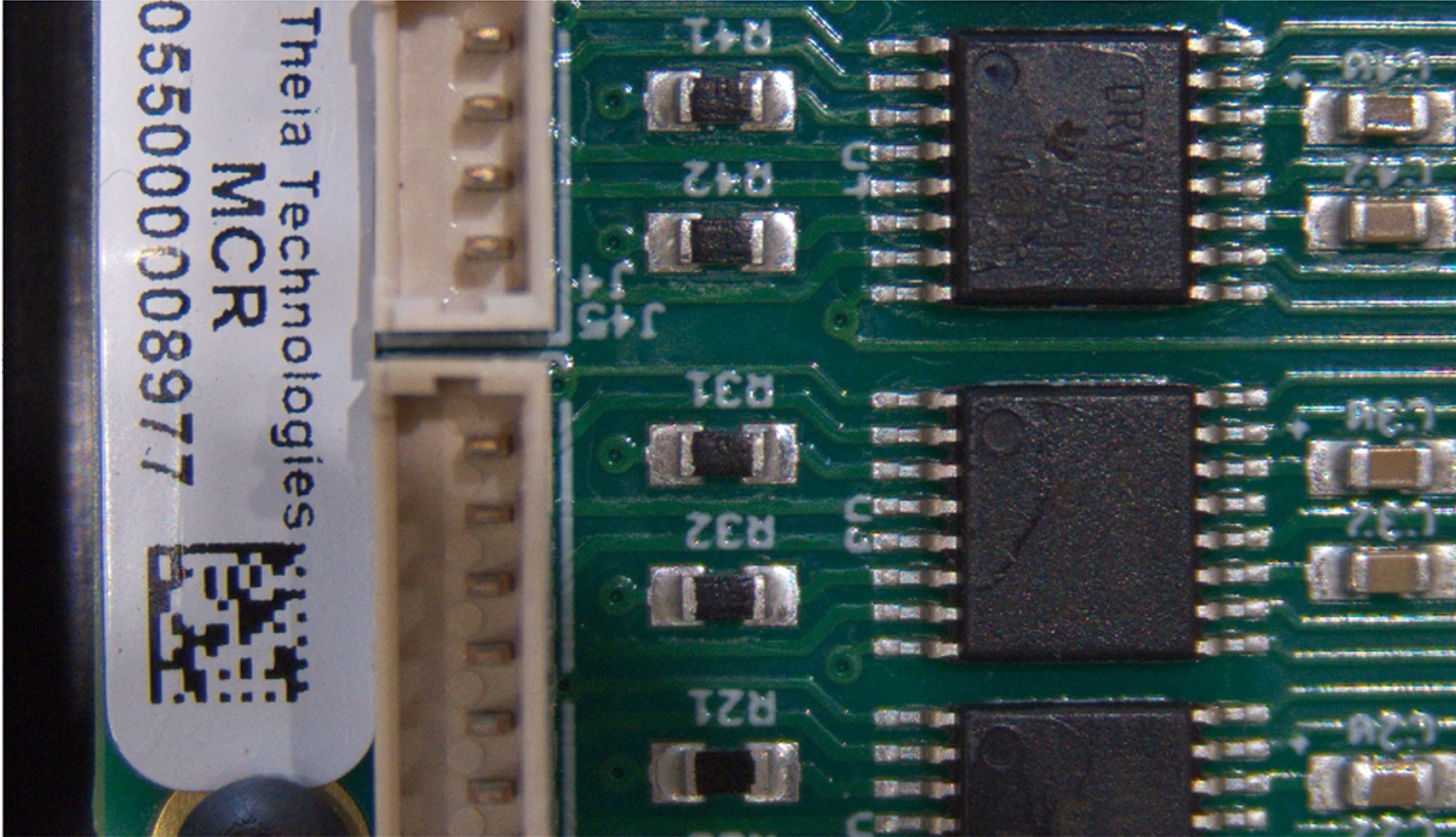

Deep learning OCR models depend on clean, high-contrast images, which in turn rely on precise optical performance. The Imaging Source's industrial camera features a 2/3-inch, 6.3 MP global-shutter sensor with 2.4 µm pixels, providing the fine pixel grid required to accurately reproduce narrow character strokes. Although the ML610M varifocal 4K lens supports pixel sizes as small as 1.55 µm, the overall system resolution was limited by the camera's sensor to approximately 200 line pairs per millimeter. Even at this level, the pairing delivers crisp, edge-to-edge detail across the sensor.

At a working distance of roughly 23 cm (9 inches), the system produced a dense, high contrast pixel grid that captured even the thinnest strokes with minimal blur, allowing the OCR operators to easily differentiate, for example, between a "1" and a lowercase "l" or a "5" and an "S".

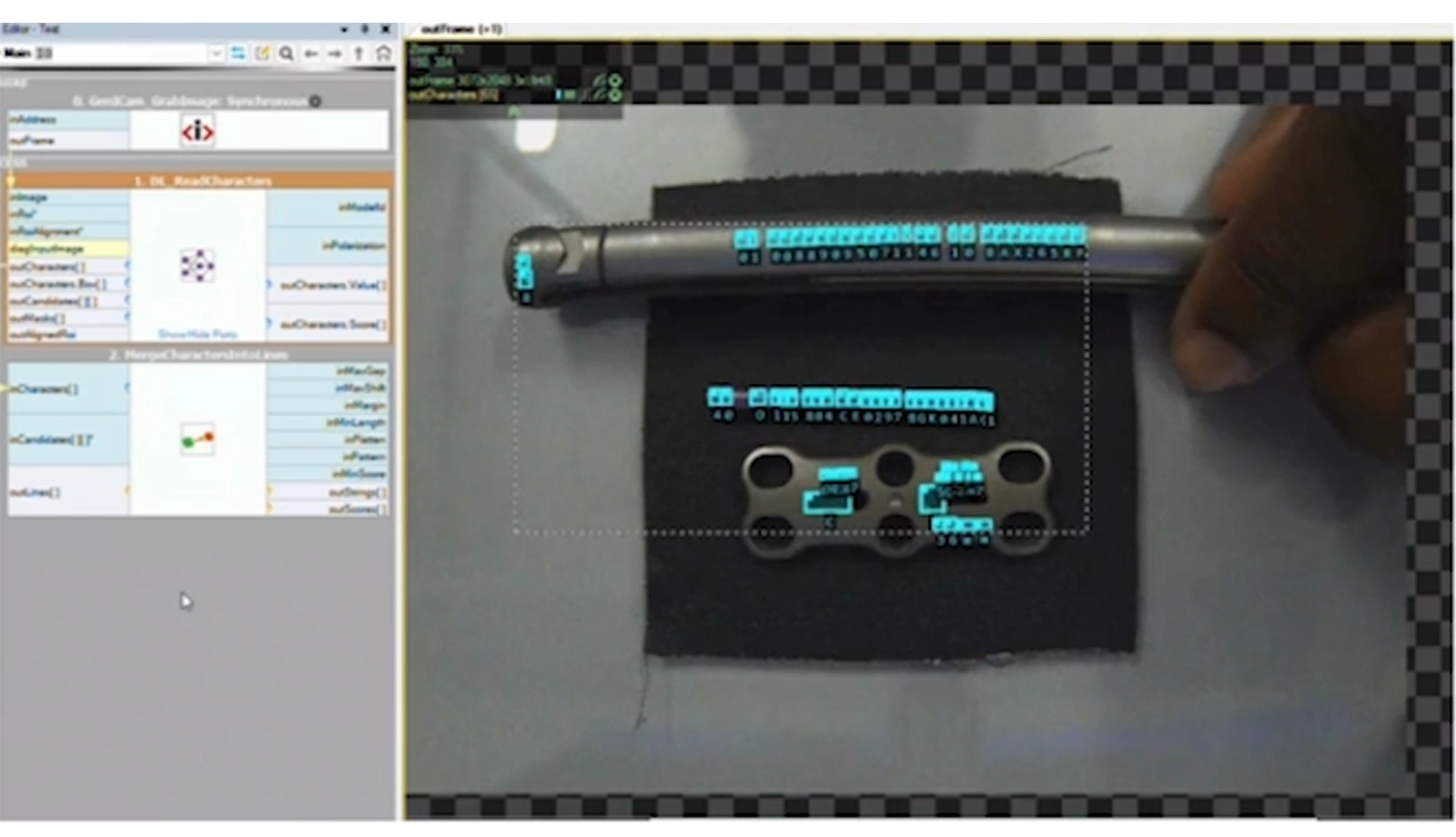

High-Quality Data for Deep Learning Confidence

The sharp image data produced by the TIS-Theia combination enabled Zebra Aurora Vision Studio's deep learning OCR functions to operate with high confidence. The DL_LocateText and DL_ReadCharacters operators rely on well-defined edges to localize and classify characters and are pre-trained to recognize a wide variety of fonts, sizes, and orientations. With about 17 pixels per millimeter at the target distance, the system supplied enough spatial detail for the network to maintain strong confidence scores (OcrResult.Score) and reduce false detections even when characters were small, worn, or slightly skewed.

The Aurora Vision Studio's intuitive, code-free environment enabled rapid testing and deployment. Parameters such as character height or contrast could be adjusted directly via its graphical interface, eliminating the need for custom programming. Combined with the mechanical stability of the camera and lens, this streamlined system setup shortened the time from concept to operation.

Results: OCR Accuracy Through Optical Precision

Results: OCR Accuracy Through Optical Precision

Testing confirmed that the optical and imaging configuration provided consistent OCR accuracy at the expected operating distance. While the ML610M's nominal minimum object distance is specified at 0.5 m, it can image at closer ranges depending on focal length (see image below). Sharp, high-resolution images were also captured at approximately 23 cm (9 inches). The combination of the DFK 33UX178 and ML610M produced the edge definition required for Zebra's OCR engine to differentiate visually similar characters.

Integrated Performance for Industrial Machine Vision

Integrated Performance for Industrial Machine Vision

The test configuration demonstrates how camera, optics, and software impact OCR performance. Together, the components formed a compact, high-precision OCR system suitable for demanding inspection or identification tasks.

The Imaging Source's portfolio of industrial and embedded cameras supports advanced machine vision applications, including OCR, inspection, robotics, and logistics automation.

Contact us to learn how our cameras integrate with leading optical and software platforms to accelerate your next machine vision project.