When (and Why) to Choose a Color Camera Without an IR Cut Filter

Published on October 29, 2025 by TIS Marketing.

Most color industrial cameras include an infrared cut filter (often abbreviated as IR Cut filter or IRCF) in front of the sensor. This filter blocks infrared light above roughly 650 nm to ensure accurate color reproduction in visible light.

Most color industrial cameras include an infrared cut filter (often abbreviated as IR Cut filter or IRCF) in front of the sensor. This filter blocks infrared light above roughly 650 nm to ensure accurate color reproduction in visible light.

For certain applications, however, removing this filter can be useful. For example, IRCF-less cameras are sometimes selected for applications requiring low-light sensitivity or improved infrared response.

For certain applications, however, removing this filter can be useful. For example, IRCF-less cameras are sometimes selected for applications requiring low-light sensitivity or improved infrared response.

The Imaging Source offers IRCF-less variants (often listed as 'DBK' variants at TIS) for many of its housed camera models. To make it easier to identify these options, The Imaging Source has added a column to the product tables (example table here) where these variants are available.

Why Most Industrial Cameras Have IR Cut Filters

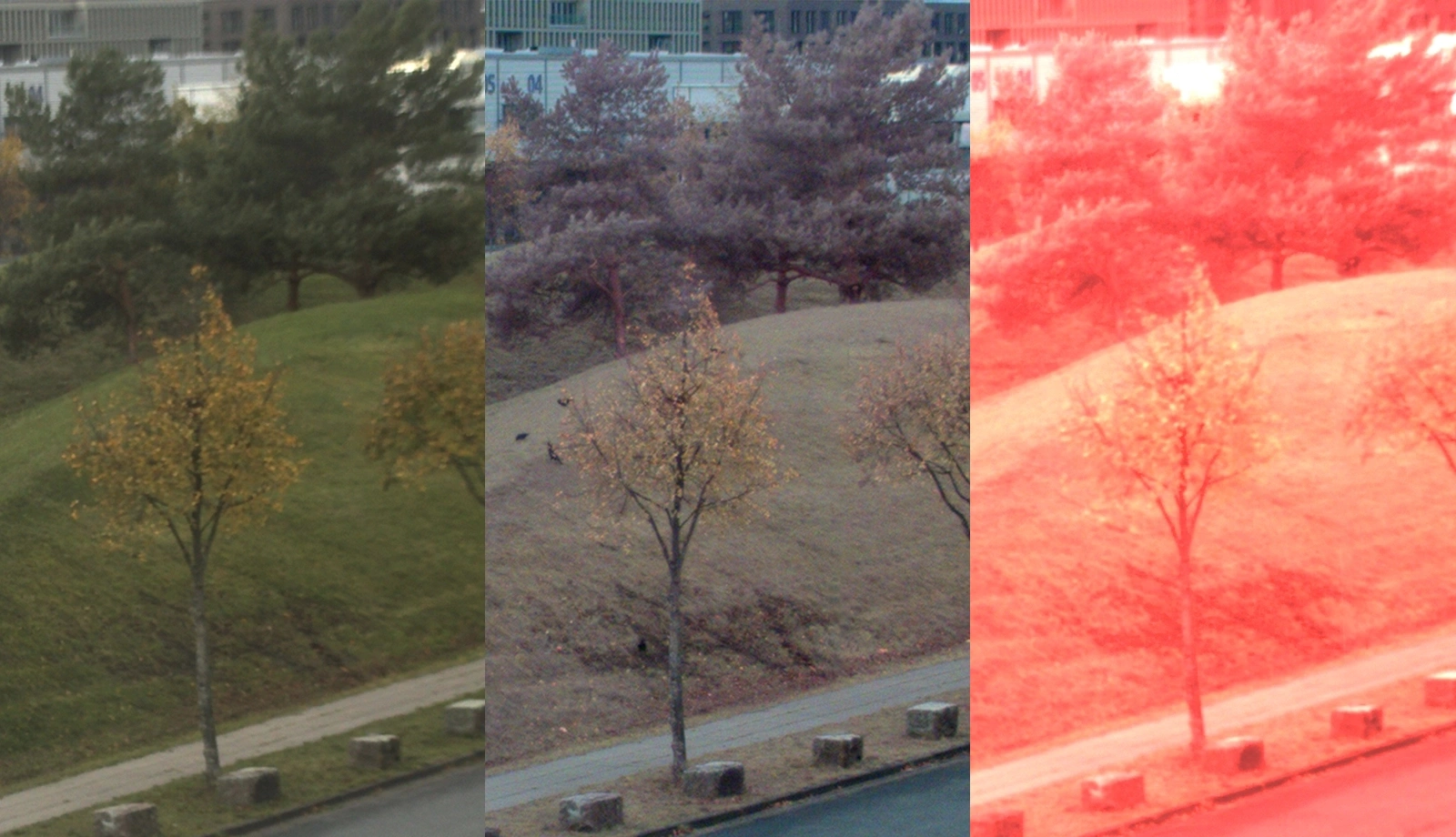

Sometimes also referred to as an IR cutoff filter, the IR cut filter blocks near-infrared wavelengths from reaching the sensor. Without it, the camera's red color channel reacts to the infrared light, resulting in color shifts to red and reduced saturation.

Sometimes also referred to as an IR cutoff filter, the IR cut filter blocks near-infrared wavelengths from reaching the sensor. Without it, the camera's red color channel reacts to the infrared light, resulting in color shifts to red and reduced saturation.

That's why color cameras are typically equipped with an IR-cut filter by default: it ensures true-to-life colors and sharp visible-light imaging.

Monochrome cameras, by contrast, are designed to use the sensor's full spectral range, including NIR, and therefore do not have or need an IR cut filter.

Why Use a Color Camera Without an IR Cut Filter?

While color accuracy is typically important for many machine vision applications, there are cases where sensitivity and flexibility are more valuable than natural color rendition.

Removing the IR cut filter allows the camera to capture both visible and near-infrared light, giving integrators or researchers more information in one image and improving performance in low-light or mixed-lighting conditions.

Typical Use Cases

Research and Laser Applications

In scientific and laboratory environments, users often want to observe light across a broader spectral range, including near-infrared.

An IRCF-less color camera can reveal how laser beams or materials behave at different wavelengths, making it useful for optical alignment, spectroscopy, or photonics research.

These cameras capture visible colors while still showing infrared emissions that would otherwise be invisible to a standard color camera.

Day/Night or Mixed-Lighting Environments

Applications such as security, traffic monitoring, or outdoor inspection often face rapidly changing lighting conditions.

A color camera without an IR cut filter can:

-

Produce usable color images during the day, even if slightly muted after automatic white-balance and gain correction.

-

Deliver higher-contrast images at night

This enables the use of a single camera for both daylight and nighttime imaging, thereby improving flexibility.

Choosing the Right Camera for Your Application

Selecting the right configuration depends on your imaging goals and lighting conditions:

-

True-to-life color imaging: Color camera with IR cut filter

-

Maximum light sensitivity or NIR inspection: Monochrome camera

-

Combined visible + IR imaging or mixed lighting: Color camera without IR cut filter

Look for the added information for IRCF-less variants in our industrial camera product tables, or contact us for advice on selecting the ideal model for your application.